Wind turbine Installation

I am currently working on installation of a 2 MW wind turbine. Lets see how it goes:

07/10/2017

Wind turbine installation begins with excavation for the foundation. The bottom is levelled with plain cement concrete (PCC). The foundation bolts required to fix the wind turbine tower is kept in postion to be embeded inside reinforced cement concrete (RCC). To fix the bolts in position, 2 flanges (top & bottom) are used which will also be embeded inside the RCC

20/10/2017

Wind turbine foundation - flange fixing

Wind turbine foundation - Reinforcement rods

Wind turbine foundation - Concreting completed

30/10/2017

Meanwhile, the turbine blades are getting ready for despatch at the OEM.

Wind turbine blade size depends on the MW capacity of the machine. The current blade has a length of about 56 mtrs and weighs about 11.5 ton per blade.

The largest wind turbine in the world has a diameter of about 176 mtr generating 9MW power (peak)

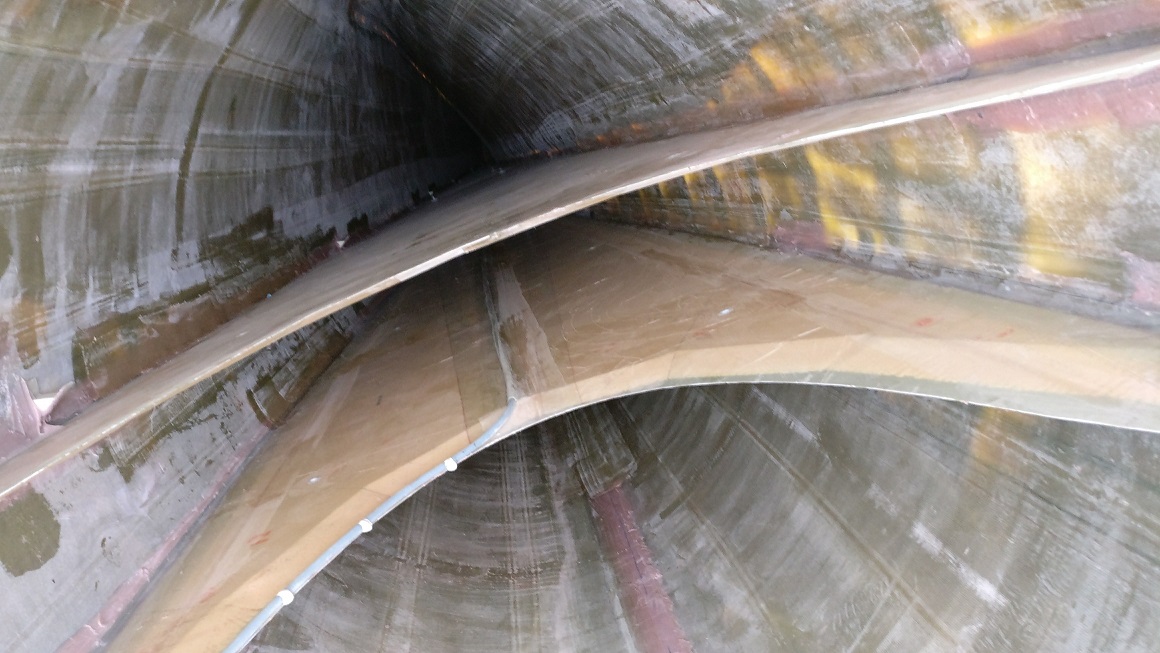

The blades are made of composites. They are hollow inside.

You can actually walk inside those blades upto a certain length. The wire seen in the picture is for the lightning arrestor.

On the blade tip, you can see the lightning arrestors and the drain holes

13/11/2017

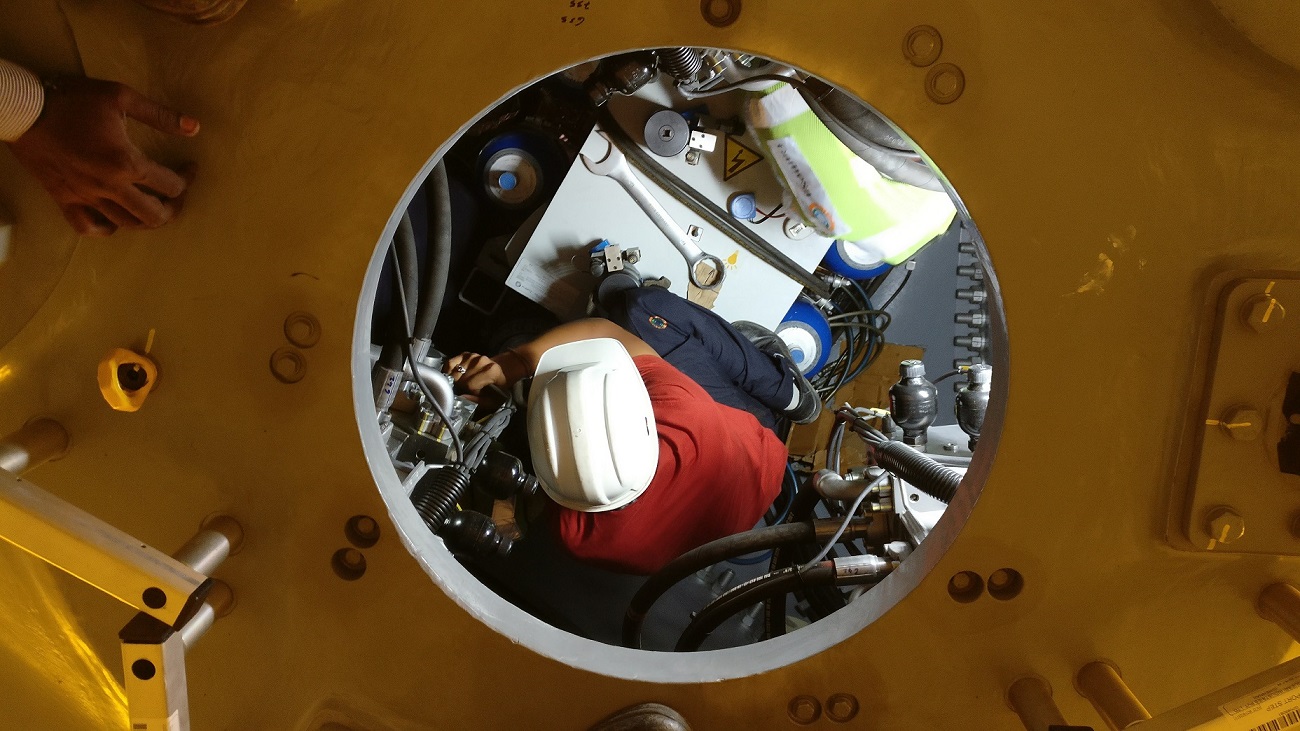

Parts arrive at site for installation. First item to arrive is the hub (The conical front portion of the turbine where the blade gets fixed)

15/11/2017

Blades arrive 2 days later

16/11/2017

Tower structure comes in 4 parts

Installation

Installation like this requires massive cranes. The crane is getting ready as the materials arrive at site

The blue / gray coloured lattice structure is the boom of the (main) crane. As the boom length increases, the lift capacity of the crans decreases. Cranes are assembled using smaller cranes. The small white coloured crans is assembling the bigger crane

17/11/2016

Tower structure comes in 4 parts. The first part is put in position and fixed to the foundation using bolts

The second section is getting ready for installation

19/11/2016

All 4 sections are erected with Nacelle on the top

Nacelle houses most of the working components of a wind turbine including gear box, generator, transformer, oil pumps etc

20/11/2016

Hub and blades are assembled seperately on the ground.

The assembly is ready for lifting

Lifting in progress

Final Position

30/07/2019 Update

The largest wind turbine available in the market is GE Halide x with a diameter on 220 mtr, producing 12 MW (peak) of power. To give a perspective on the size of the blades, the new GE blades are as long as my tower itself.